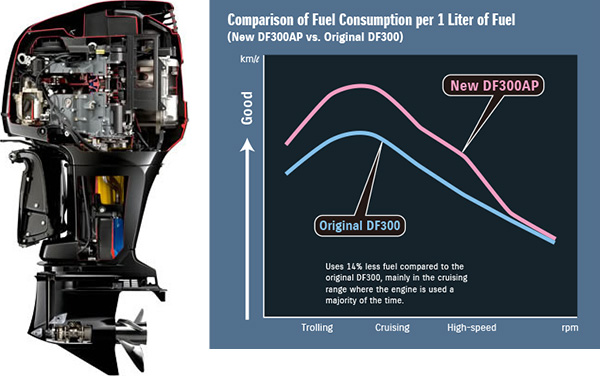

Suzuki's Lean Burn Control System

Suzuki's innovative Lean Burn Control System was first introduced on the DF90A/80A/70A to great acclaim from boaters and

the media alike. It predicts fuel needs according to operating conditions allowing the engine to run on a more efficient

fuel mixture through the use of a lean air-fuel ratio. It delivers its benefits over a wide operating range, providing

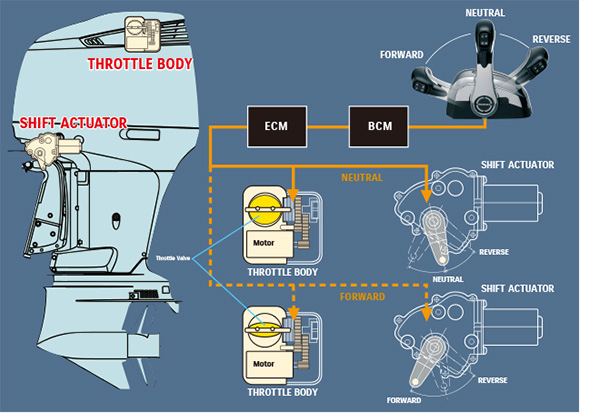

significant improvements in fuel economy from low-speed operation into the cruising range. Combining this system with

the Suzuki Precision Control electronic throttle and shift system allows the operator precise control over engine RPM

for improved fuel economy over a wider operating range. This combination also delivers smooth power transitions

throughout the entire RPM range. In-house testing shows that while cruising, the DF300AP is 14% more economical than the

original non-Lean Burn DF300 without sacrificing any power of the original DF300.

Data used in the graphs were obtained through in-house testing under uniformed conditions. Results will vary depending

upon operating conditions (boat design, size, weight, weather, etc.)

Cleaner, More Efficient Operation

Suzuki's advanced four-stroke technology delivers cleaner and more efficient operation that conforms to the Recreational

Craft Directive (RCD) – Directive 2003/44EC of the European Parliament and of the Council, and has received three-star

ratings from the California Air Resources Board (CARB).